RapidRobot

The next generation robot controller is here. RapidRobot is a powerful robot controller which provides users with an intuitive interface for programming, simulating, and manipulating robots in real time.

Overview

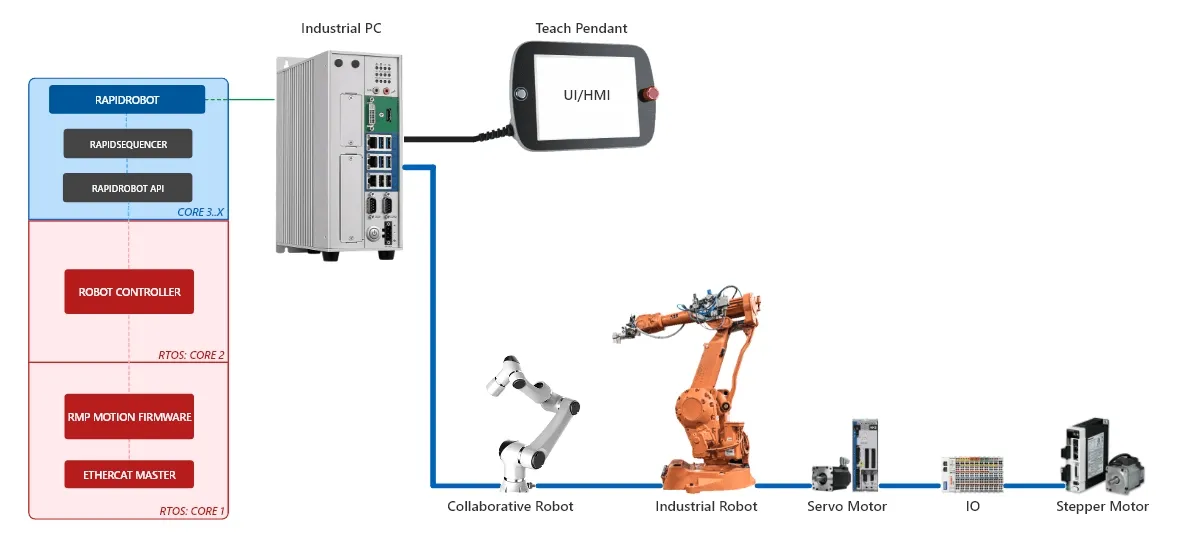

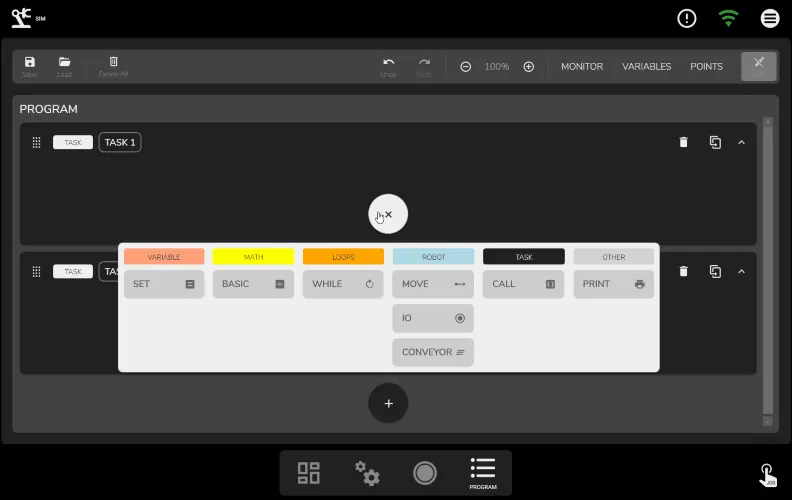

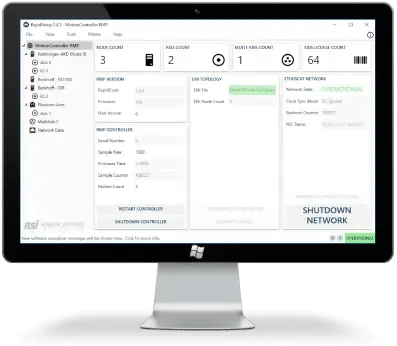

A robot controller that leverages RMP soft motion controller. Many applications can be programmed entirely with the RapidRobot UI

A script that can be loaded into the robot controller to create a customer user block for any customization

Use the RMP motion controller for your machine and RapidRobot for additional robot(s) using single controller.

A user can add additional EtherCAT compatible slave devices in addition to the robot. (servo, stepper, or IO)

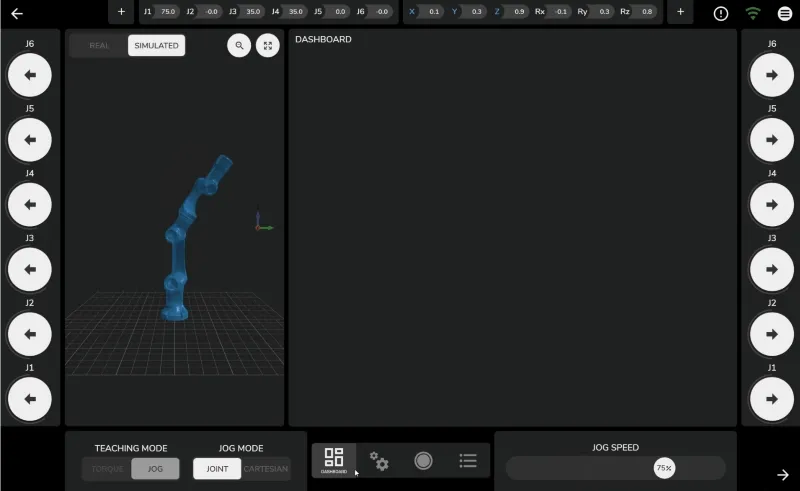

Perform the same same joint space and cartesian space jog and teach operations as with a Teach Pendant

RapidRobot software can work with any EtherCAT compatible collaborative, industrial, delta, or SCARA robot

You can use RapidRobot software to control up to 11 robots simultaneously

Collect or modify robot moves using our timestamps in a real-time deterministic network

Robot programs can be created and edited offline

Architecture

A plugin that allows our open RMP EtherCAT soft motion controller to be work with RoboDK’s Robot software user interface.

RapidArm Components

Recommended hardware

Surface Pro

Dimensions (HxWxD): 292 x 201 x 8.5 mm

Screen Size: 12.3 “

Resolution: 2736 x 1824

Weight: 784 g

Style: Wired or Wireless

Robot Controller

OS: Windows 10 32/64 bit

Core Support: 6th generation Intel® Core™ i7/i5/i3 LGA1151 socket type processors

Chipset: Intel® 100 Series

Display Support: 1 x DVI-D, and 1x HDMI for dual independent

LAN Ports: 3 x Intel® GbE LAN ports; support WoL, teaming and PXE

USB Support: 4 x USB 3.0, 2 x USB 2.0 and 2 x RS232/422/485 auto

Power Support: +24VDC input & ATX power mode.

RapidRobot Software

Intuitive user interface

The Most Intuitive Controller For Cobots

Enjoy the ultimate robot program editor. Creating programs is like using a mobile application. It brings an advanced design interface to the robotic industry that both beginners and experts will fall in love with. It's incredibly smart, super flexible, amazingly powerful and visual by nature. This is how programming a robot is meant to be done.

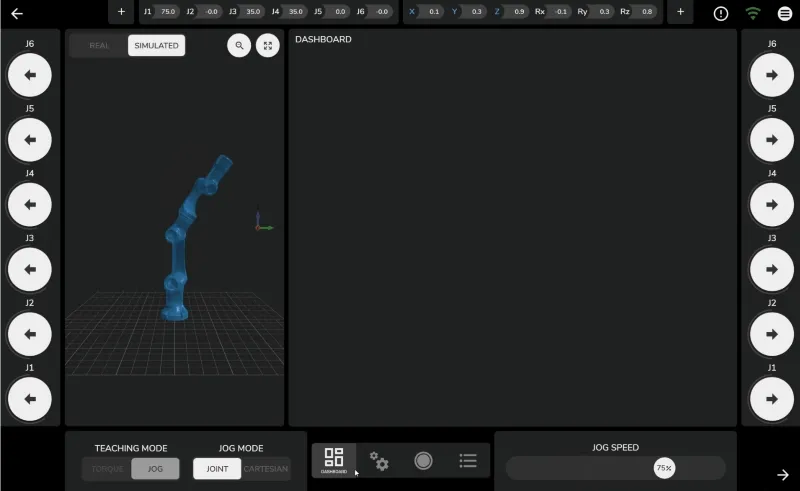

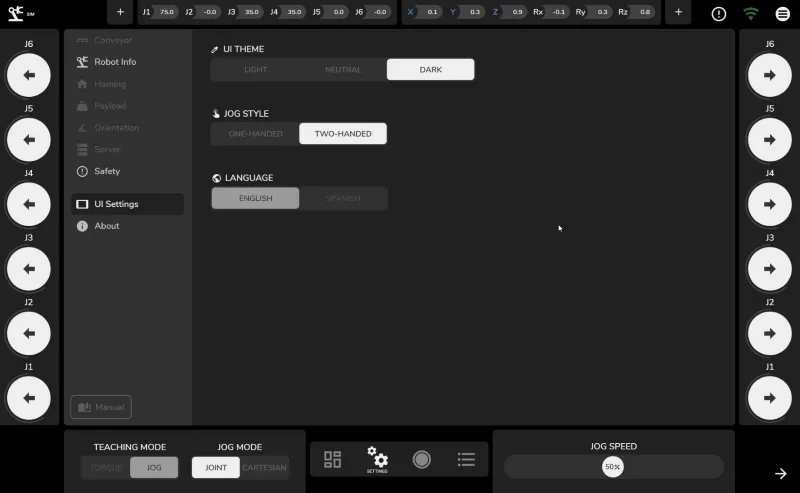

Moving a Robot Has Never Been Easier

With our software, moving your robot to is extremely easy. You have complete freedom to jog in Joint or Cartesian space. Easily change speed, modes and save points. With our animations you will know exactly what part of the robot is moving and when certain limits have reached. Controlling a robot has never been this easy and fun!

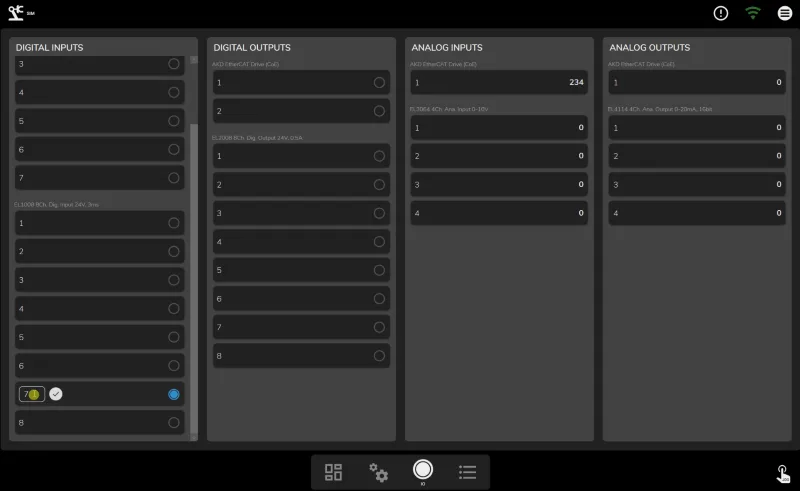

Inputs and Outputs State and Manipulation

Troubleshooting and configuring IO all in one place. Easily modify the state of each individual component or simply observe how your program is changing the state of your available IO.

Different Flavors For Different People

Here at RSI we see how different popular technologies and trends evolve and it is our goal to stay current with technologies that might make our customers life easier. The RA Software allows you to change the theme, the jogging style, and the language. These are just the first custom items of many more to come!

Try Our Free Trial!

Sign up for a 30-day software evaluation.

An Engineer will assist you shortly.

start developing today!

1000+ customers have already automated with help of our products and team